|

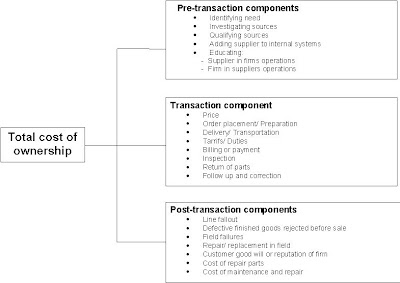

| Total cost of Ownership in global sourcing |

Global Supply Chain Management

Sunday, 21 October 2012

Wednesday, 3 October 2012

Tuesday, 21 June 2011

Logistics of LCC Sourcing

Monday, 6 September 2010

Moving out of Supply Chain after economic crisis

Purchasers and supply chain executives caution - during economy rebound

Understand & ensure that the supplier is well informed – Recession has hit every on in the chain (Since its supply chains competing against each other and not companies). So it is important to ensure that the supplier is informed of the rebound and make a personal visit. This visit can ensure the availability of capacity, employee skills and a reaudit of the capability of the suppliers to bounce back. This is also a time for the OEM’s or supply chain captains to understand and listen to the problems of the suppliers. Its also worthy to ask how the supplier has survived the recession, to understand the resilience of the supplier.

Go till the tier 2 – Though most companies try to manage only the tier 1 companies, it is important to reuderstand the tier 2 companies of the supply chain. This ensures that the supplies are being streamlined and also that the tier 2 is able to ramp up production.

Check for new opportunities – Rebounce is a good time to check the existing structure of the supply chain. Check for new opportunities with existing suppliers and also check for new suppliers for old activities. New opportunities might open up because of technological changes, new cost reduction opportunities, change in supplier role and availability of new and better suppliers.

Monday, 28 December 2009

International purchasing and environmental sustainability - Can they co exist ?

After the Copenhagen climate change conference there has been an increasing interest in purchasing, logistics and supply chain professionals about how they can contribute towards making the world a better place. This is evident in the increase in the number of articles from supply chain magazines on environmental sustainability. Some people perceive international purchasing bestowed with poor environmental sustainability. However I choose to argue the opposite with the following reasons.

Multinationals have raised the need for addressing sustainability globally - With the increasing number of multinationals in developing countries, there is an increasing need to ensure that their suppliers are environmentally sustainable to be as suppliers to them. Hence multinationals have served as a major driver in creating awareness and systems for environmental sustainability. We know from the climate change that sustainability needs to be addressed as a global phenomenon and not as a local/regional phenomenon.

Intermodal transport is a great need - Russia has recently inaugurated a gas pipeline of more than 2250 km from Russia in to East Asia. This event will invoke discussion about the trans-siberian railway network which is supposed to connect China and Europe. With this network inline it would perhaps be less carbon intensive to transport goods from China in to Northern Europe when compared to truck transportation from southern Europe. Hence with such infrastructural and governmental level involvement it is possible to make international purchasing co exist.

Planning for sustainability - Products that are based on platform design, where there is a large amount of standardization and modularization involved could result in better predictability of demand, reduce variation, reduce obsolescence risk and also increase the scale of sourcing volumes. This could be coupled with postponement of manufacturing to nearby customer locations. Such logistics strategies increase environmental sustainability but still make it viable for international purchasing.

Cross functional integration - International supply locations act as good sources of sustainable designs and hence act as good reason to source from them. In order to adopt these good practices from international locations there is a need for good cross functional integration in the company. This aids better understanding of internal requirement and also external opportunities/ideas.

Tuesday, 22 December 2009

Supply chain quality - Going beyond functional silos

Large amount of energy and efforts have gone to develop frameworks for quality management in companies. TQM, TPM, ISO certification, Lean practices, six sigma quality are some exemplars of such frameworks focused on developing quality. However there are certain fundamental questions that are unanswered by these questions.

- When some companies are having more than 50% of their value addition from their supply base, is having these quality management focussed on internal company sufficient?

- At best what is visible when it comes to external supply quality management is objective performance monitoring - Can all quality parameters be objective in its nature and controlled by just measuring quality of supplies?

- Most of the internal quality management focusses on continuous improvement and companies have asked their suppliers for Kaizen, lean and other practices to harness the benefits of continuous improvement - But is continuous improvement preferred over rapid improvement considering rapid product changes, increasing need for radical innovation?

- Supply chain has focussed so much on the process way of managing things, How much is quality managed from a process perspective?

- Should quality be the issue of the quality department or be integral in the supply chain - if integral how do we implement and measure them?

- How should proactive thinking be integrated in the supply chain quality management?

Friday, 11 December 2009

Differentiating disturbances and disruptions in supply chain

When we talk about risk management in supply chains there are two typical parameters used in risk evaluation. They are severity of impact and the probability of occurrence (refer figure). This method of looking at risk has its roots in FMEA, where severity of the impact, frequency of occurrence and ability to detect are used as methods to assess risks.

It is interesting to differentiate between disturbances and disruptions. This helps to choose what type of strategies needs to be considered for different types of risks. Disturbances are high probability and low impact kind of events that needs to be constantly looked after. An example for this is the operational disturbances that companies need to handle constantly in supply chains. Disruptions are events that have low probability o occurrence but they have a high degree of impact in the supply chain. An example of this could be related to how the supply chains were affected during 9/11 attacks, Tsunami etc.., where these events do not occur on a daily basis, but when they occur there is a big impact on the supply chains.